is hardness testing destructive|ndt full form in engineering : bulk Destructive Testing (DT) and Non-Destructive Testing (NDT) are two different approaches used to assess the properties, integrity, and performance of materials, components, or structures. Tensile Testing. Hardness Testing. .

webAn epic is a large body of work that can be broken down into a number of smaller stories, or sometimes called “Issues” in Jira. Epics often encompass multiple teams, on multiple projects, and can even be tracked on multiple boards. Epics are almost always delivered over a set of sprints.

{plog:ftitle_list}

WEB2 de nov. de 2020 · 什么是Neteller?Neteller电子钱包是一种在线支付工具,Skrill和Neteller电子钱包由同一母公司Paysafe Group拥有。因此,这两种钱包的政策和功能几乎相同。您可以在这两种类型的电子钱包之间来回转账。neteller 功能 用户之间转账 购买数字货币 如何注册&创建

A hardness test uses a limited compressive force to apply a small deformation to the surface of a material, in order to assign a relative value for the material’s hardness. However, a ductility test uses a destructive tensile .

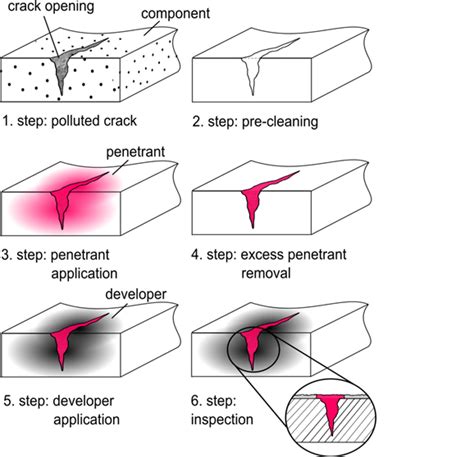

Nondestructive testing (NDT) or Nondestructive evaluation (NDE) is a method of materials testing to assess the characteristics of a component without altering or destroying it. NDT is important in the materials .

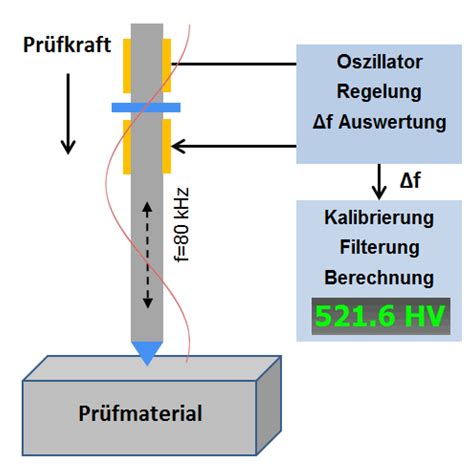

uci method for hardness testing

types of ndt weld testing

Around 1900, Martens proposed the following definition for hardness testing: “Hardness is the resistance of a body to the indentation by another (harder) body.” This simple but precise definition has taken its place in technical .A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by .Hardness testing is crucial for assessing the strength, durability, and wear resistance of materials. It helps determine the suitability of a material for specific applications, ensuring quality control and reliability in critical components .Destructive Testing (DT) and Non-Destructive Testing (NDT) are two different approaches used to assess the properties, integrity, and performance of materials, components, or structures. Tensile Testing. Hardness Testing. .

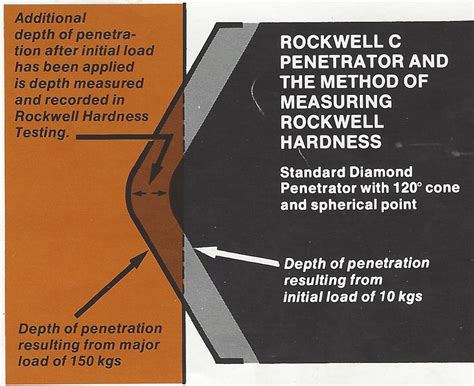

Destructive testing is a method used to assess the strength and durability of materials by subjecting them to various loads and stresses. This approach involves intentionally pushing materials beyond their limits to observe how .The most common Rockwell method in practice is HRC. In principle, ball indenters are used for the hardness tests on softer materials and diamond indenters for testing harder materials. The diamond would destroy softer . Hardness testing such as Vicker & Rockwell hardness requires the test surface to be prepared by fine polishing to measure the accurate indentation size & hence the material need to be destroyed- So, one can consider it .NDT Group employs a range of advanced equipment and techniques for Hardness Testing, including Rockwell, Vickers, and Brinell Hardness Testers for different materials. Additionally, we utilize Microhardness Testers for small or .

Non-destructive Testing: Leeb Rebound Hardness Test, is one of the four commonly used methods to test the hardness of the metal. It is non-destructive used to inspect workpieces weighing above 1 kg. 2. Excellent .While traditional hardness testing methods can be considered destructive to some extent, non-destructive alternatives are available for applications where surface integrity is a concern. It is important for industries to carefully consider the potential impact of hardness testing on their materials and choose the most appropriate testing method .Leeb Hardness Tester Series. Leeb Hardness Tester; Search for: Search. Product categories. Flaw Detector Series. Magnetic Flaw Detector; Other Flaw Detector; . A Complete Guide NDT (Non-Destructive Testing): A Complete Guide NDT (Non-Destructive Testing) Equipment Non Destructive Inspection Non Destructive Examination: A Complete Guide Follow .

Please cite this article as: K. Buranapunviwat and K. Sojiphan, Destructive testing and hardness measurement of resistance stud welded joints of ASTM A36 steel, Materials Today: Proceedings, https . This type of destructive testing helps assess the hardness characteristics of metals, polymers, ceramics, and other materials. There are various methods available for hardness testing, including the Brinell, Rockwell, and Vickers tests. Each method employs different techniques to measure the material’s resistance to penetration by an indenter .Hardness testing can be considered non-destructive when used on the components’ surface and a hardness impression is not objectionable. Simple enough when the surface is typical of the bulk of the component and the configuration is accessible for performance of the test

Hardness testing is more along the lines of a destructive test in purpose, in that it is gauging the physical properties of the material. The most common NDT methods (for those who aren't familiar) are visual, magnetic particle, liquid penetrant, radiographic, and ultrasonic.Rockwell Hardness Testing Services. The Rockwell Hardness Test is one of the simplest and most cost-effective HT techniques. It measures the depth of penetration of an indenter under a large load, compared to the penetration made by a preload. The permanent deformation caused by the larger load offers information on the material's hardness. 2. What is NDT? • Nondestructive testing or non-destructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. • The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive . Is hardness testing destructive or non-destructive? Hardness testing is utilized on component materials to determine how effectively the material resists indentation, providing insight into how it will perform over time. This form of destructive testing shows how materials are affected by stress and how components will wear once performing in .

portable hardness test explained

Non-Destructive Hardness Testing. Nondestructive testing (NDT) or Nondestructive evaluation (NDE) is a method of materials testing to assess the characteristics of a component without altering or destroying it. NDT is important in the materials testing industry where quick, dependable information on finished or raw material is needed. . 11. Vicker Hardness Test:- The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in . 4. Hardness Testing. Hardness testing is a mechanical testing method used to determine the resistance of a material to permanent deformation, such as scratching, cutting, or indentation. It is an important measure of a material’s strength, durability, and wear resistance. There are several main types of hardness testing:Hardness testing makes it possible to determine material characteristics such as strength, ductility and wear resistance. It also shows whether the heat treatment process has been carried out properly.

Destructive test - Download as a PDF or view online for free. Submit Search. . Hardness Test Antonius P. Bramono - [email protected] 31. • Weldment designs that include areas such as flanges and extensions .Study with Quizlet and memorize flashcards containing terms like Destructive testing involves subjecting weld samples to loads until they fail., Before a specimen is placed in a tensile testing machine, an accurate measurement of .

This article presents a short overview of the most common techniques in non-destructive testing (NDT) of ceramic matrix composites (CMCs), including measurement of hardness.

Historically, such assessments have systematically required destructive tests (hardness testing [7], X-ray analyses [8]), which involve additional costs and the loss of valuable components. Nowadays, alternative non-destructive methods have been developed [9, 10].Rockwell Hardness Testing: Recognized for its quickness and simplicity, Rockwell hardness testing measures the depth of penetration by an indenter under a large load compared to the penetration made by a preload. . has completed the installation and commissioning of their new Nondestructive testing (NDT) line. The new line, along with . VICKERS HARDNESS TESTING M FACTS Advantages of Vickers hardness test The Vickers method can be used with any and all materials and test specimens, from soft to hard. The procedure covers the entire hardness range. There is only one type of indenter, which can be used for all Vickers methods. Non-destructive testing is possible, so the test .Hardness Testing. Hardness testing involves determining surface hardness of a material and is done through the following methods. Indentation Hardness testing - The basic principle, as with all common measures of hardness, is to observe the questioned material's ability to resist plastic deformation from a standard source.. Non-destructive hardness testing (NDT) - .

We would like to show you a description here but the site won’t allow us. Re: ASTM A106 Gr B Hardness Reference value In Reply to Phil Herman at 19:31 Jul-26-2010. Hi Carlos Section 3 is ordering information requirements and hardness testing is not there, nor in the rest of the body of the specification. Mechanical properties does not include Hardness values, so any requirement must be application driven. The results of the nanoindentation test provide the necessary data for the analysis of the elastic modulus, hardness, strain hardness, cracking, phase transformations, creep and fracture toughness of the material. The sample size and sinking effect are very small, so it is considered a non-destructive test.

The Rockwell Test. The Rockwell test was invented by Stanley P. Rockwell. He was a metallurgist for a large ball bearing company and he wanted a fast non-destructive way to determine if the heat treatment process is performed on the bearing races was successful.

ndt testing full form

Non-destructive test (NDT) is a testing method that evaluates the physical properties of a material or component without causing any damage. In contrast, destructive tests (DT) involve assessing the properties and performance of materials and products by subjecting them to extreme conditions until they fail. . Hardness Testing. Hardness .

ndt full form in engineering

eddy current hardness testing

eddy current hardness tester

56 mil views, 378 likes, 1 loves, 458 comments, 99 shares, Facebook Watch Videos from UOL Notícias: Brasil tem 1.623 mortes por covid-19 em 24 h e supera 13 milhões de casos O Brasil registrou nesta.

is hardness testing destructive|ndt full form in engineering